Gathering members of the press at London’s most prominent skyscraper, The Shard, members of the Perkins team painted a comprehensive picture of the projects that have been occupying the company in the last few years and will be shaping the off-highway industry for those to come

The backdrop for the day was the new company rebrand. Inspired by what uncertainties and challenges are plaguing customers, what social pressures they are having to deal with, what expectations are being set for them, and the fact they are operating in an unprecedented period of relentless change (with multiple power solutions becoming available to them), Perkins has refreshed its brand with the new tagline: ‘Together, we power ahead’.

This was being adopted (as a revitalisation to its predecessor: ‘The heart of every great machine’) as a call to power connections, bring ideas together and ultimately drive change through a more agile, smarter offering. With it, comes the Perkins promise to deliver smarter solutions to advance sustainable power in integrated solutions with higher productivity and lower costs.

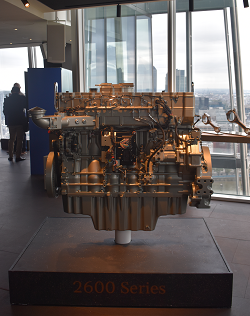

Nowhere is this new ambition more apparent than in the new, next-generation 13-litre diesel engine, designed for demanding applications across agriculture, construction and other off-road applications.

The Perkins 2600 Series was, according to Allen Chen, product marketing manager, who presented in London, delivered upon the understanding that what customers want “is not another evolution, but a revolution.”

In appreciation of this, the 2600 Series engine platform (the origins of which can be found as early as 2017), has been designed to achieve best-in-class power density, torque and fuel efficiency for heavy duty off-highway applications including agriculture tractors; harvesters; wheel and track loaders, excavators, dozers and other construction machinery; heavy lift trucks alongside a wider range of material-handling equipment; and large industrial pumps and compressors.

It extends the company’s portfolio with eight power ratings from 340 to 515 kW, offering up to 3,200 Nm of peak torque and is delivered to perform in extreme conditions such as high altitudes and temperatures.

In a nod to the growing concern of environmental impact, Perkins will offer the 2600 Series engines configured to meet the emissions standards of higher-regulated countries (such as EU Stage V) alongside versions for countries with lesser regulations.

Further emphasising Perkins’ commitment to sustainability, the engines are also compatible with renewable liquid fuels such as 100% hydrotreated vegetable oils (HVO) and B100 distilled biodiesel. It also boasts a number of upgrades that results in lower fluids consumption and extended oil and fuel filter service intervals as long as 1,000 hours, reducing operating costs and downtime.

“The new Perkins 2600 Series engine platform demonstrates how we’re leveraging our experience, intelligence and commitment to help OEMs navigate the energy transition with power solutions that deliver exceptional performance on the worksite,” said Jaz Gill, vice president of global sales, marketing, service and parts.

Looking ahead, the 2600 Series is expected to become available for early OEM pilots in 2025 before the launch of commercial production in 2026.

Expanding the portfolio

The 2600 Series was not the only ambitious project outlined in London with a view to meeting customer challenges of the future. A new concept – barely six months old – was also unveiled by the Perkins team; now being pursued with a primary focus on smaller OEMs and a diverse range of applications.

Project COEUS, named after the Greek titan god of intelligence and curiosity, is an advanced integrated power unit representing a robust plug and play power solution, delivering consistent power system performance regardless of fuel type, reducing OEMs design integration demands and OEMs Power Systems Installation Validation and A&I demands.

The advanced system integrated into a compact ‘drop-in’ solution for flexible lower-carbon intensity power is expected to benefit from advanced digitisation such as online system optimisation, advanced hybrid systems and an advanced Spark ignited LCI ICE platform.

It was indicated that a demonstration machine could be produced in around three years and more information about the project will be being released in the near-future.

Alongside this, the Perkins presenters drew further attention to innovative advances the company is pioneering including its work on electrification – where a reportedly significant amount of time has been spent to develop the company’s product range.

Its portfolio includes 48-, 300- and 600-volt lithium-ion battery solutions with modular designs and factory-installed telematics. It was made clear that, while batteries are available to customers today, the company is anxious to progress and learn with its clients, to continue to enhance performance and packaging for next-generation off-highway applications. A battery was on show in London, with six modules on each side as an example of a 300-volt and 600-volt solution (the size is the same although the 48-volt version is smaller). It was stressed that the design has been specifically targeted to ensure customers are able to install the solution in a simplified way and consistently applied to applications in the market.

Comprehensive support

While much attention was focused on the new innovations Perkins being brought to life for the market, there was time to reflect on the existing products powering operations onwards across the globe and celebrate the support the company offers to keep these functioning effectively.

Speaking in London, Matt Burton, Perkins aftermarket & lifecycle & commercial manager, estimated there were around 4.5 million Perkins engines or powered equipment in circulation right now, performing productively in around 5,000 different applications. This is an impressive boast for the company, but it means that there is a wide array equipment owners counting on Perkins to ensure they can meet their objectives.

This responsibility is not, however, taken lightly by Perkins whose Aftermarket Services offer a lifetime of engine support to maintain support and extend product life – from the moment of purchase, through to replacement of engine. Its network of 88 distributors are there for customers in 185 territories with expertise, parts and support trained by Perkins to ensure low cost of ownership.

From initial purchase, customers can register their product with the Perkins My Engine App which provides everything they need to manage the engine in the palm of their hands. They can also elect to purchase Perkins Platinum Protection as well as the standard warranty that is offered. According to Burton, this support beyond the standard warranty period delivers peace of mind and provides access to as much as 10 years and 15,000 hours’ worth of cover, with no exceptions for harsh environments. Then, there is Perkins Hypercare, a comprehensive package of life cycle services tailored to customer’s engine needs.

Under Perkins’ wing, customers can maintain the performance of their engines with convenient kits providing all required parts in a single box and extend the life of their engines with repair solutions and overhaul kits to ensure value is retained. Finally, Burton expressed the support even at the end of life, with a full range of options to ensure customers are fully covered with a choice of repower machines and replacement solutions.

“My team are always looking ahead and it’s our job to be ahead of customer problems before they are already there… we are going to be there with a lifetime of support, whatever the power solution,” remarked Burton.

Speaking to African Review following his presentation, Burton took pride in the fact all the aforementioned aftermarket support services are fully-available to the African continent. The promise of full support, he continued, is very much global, reiterating this (with access to patented Perkins components) is the best way to ensure product longevity, minimise downtime and ultimately lower cost of ownership.