Despite often being regarded as a burdensome expenditure; inadequate ventilation investment can lead to higher costs in the long-term

Ventilation has long been a central factor in the effective running of mining operations. In the earliest ventures underground, it has been reported how miners utilised strategically positioned fire throughout tunnels in order to encourage airflow and deliver unpolluted air into the lungs of those within.

As the years have progressed, the sophistication of scientific practice has enhanced the understanding around ventilation and its centrality to miner health, which has combined and contributed to a growing emphasis on worker welfare.

In turn, the increasing amount of time, investment and expertise dedicated to this part of the industry has led to a rapid advancement in technology and methods. As such, the underground bonfires and sentient monoxide detectors (canaries were a common site in many of Britain’s underground mines of the early 20th century) have now been replaced with mechanical fans, cooling and heating systems, detection and monitoring devices, alongside new digital solutions.

Every year, new advancements are delivered to the market to add to this assortment, so operators have never had more means at their disposal to ensure equipment is kept safe and all those who arrive on site, return home at the end of the day in the same condition.

In correspondence with African Review, Russell Hattingh, managing director at BBE Consulting, outlined how ventilation has always remained a key consideration in mining as “if suitable conditions are not present in a mine, mining stops, as mining staff cannot physically function with limited air and high ambient temperatures.”

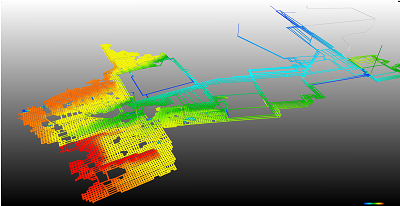

He continued, “Certainly in the last two decades, advances have been made in terms of ventilation modelling allowing an optimisation of mining activities. Ventilation and cooling needs to be planned carefully. In the commercial sector a design can be provided for a building as the envelop is fixed. The usage and occupancy may change but the structure of the building is fixed providing clear boundaries for a design.

“In mining one has to follow the orebody, which may or may not yet be fully characterised. The time frame for mining is also many years so the build-up is important and ventilation systems should be suitably flexible to support both short- and long-term mining plans. Modelling allows a clear understanding of the mine, how it will grow and how it can be ventilated and cooled.

“Given that starting a mine is expensive as initial development may not be in the orebody and therefore not revenue generating capital deferment is often essential. Understanding the ventilation and cooling build-up of a mine enables mining companies to plan their systems and therefore their cashflows. Ventilation and cooling systems are also energy intensive, since huge volumes of air must be circulated through a mine (and often cooled) to provide fresh and suitably conditioned air for personnel and equipment.”

According to Hattingh, in South Africa especially, ventilation is not being overlooked, with companies paying careful, diligent attention to this aspect. Mining organisations, he described, must now ensure the safety of their personnel and this is the foundation of companies’ value systems.

“Slogans like Goldfields ‘if we cannot mine safely, we will not mine’ show the attitude of mines towards safety. It is value number one. Ventilation and cooling systems do not fall into the nice-to-have category. They are vital safety systems,” Hattingh said.

“Without suitable ventilation mining stops. Equally (and perhaps less dramatically) without careful planning, ventilation will constrain mining operations (which could delay production ramp-up). BBE believe that ventilation should be an enabler for mining and not a constraint but this doesn’t just happen. Planning and coordination with the mine planning team is essential. Vent and cooling are expensive (from a capex and opex perspective), and given that initial capital may be constrained, understanding what makes up these costs and the timing of costs is important and can make or break a project.”

When asked why investment in correct mine ventilation practices is a good option for long-term prosperity, Hattingh replied, “Two words: regret spend. Buying equipment without the future in mind means that you will end up buying equipment to satisfy the short-term. In the long run this is expensive since you could end up buying equipment you cannot reuse. The lead time of installing suitable mining infrastructure (such as shafts) and major equipment is also long so a delay could ultimately result in extreme working conditions or scaled down production rates.”

BBE has now been providing ventilation and cooling solutions for the last 30 years and has been a key contributor to developing the science behind ventilation systems. Hattingh concluded, “I would like to think we’re pretty good at what we do and that we keep getting better. We follow a rigorous process of internal reviews to ensure the quality of our work is maintained.”

Read the full ventilation article, including the advancements being undertaken by Air Blow Fans and Howden in the latest issue of African Review: https://www.africanreview.com/magazine-archives/african-review-september-2023