In The Spotlight

Launch of the facility will enable the African Development Bank to increase the reach of the CAW's efforts. (Image source: AfDB)

African Development Bank (AfDB) has unveiled its new Climate Action Window (CAW) Technical Assistance Facility at COP29

Before the conference, which is running in Baku from 11-22 November, the organisation stated its intention to mobilise additional resources for climate action in Africa and to launch a new approach to assess African economies. Following this, it has taken a ‘major step’ to address the continent’s climate finance gap by launching a new funding call with an initial allocation of US$56mn.

The CAW Technical Assistance Facility will support the preparation, financing and implementation of adaption and mitigation projects aligned with the Paris Agreement, Nationally Determined Contributions (NDCs), and National Adaption Plans (NAPs). It will aim to transform the development of climate projects across 37 low-income countries in the continent and is backed by funding commitments from partners such as the United Kingdom, Netherlands, Germany, and Switzerland. It will be accepting proposals from governments, regional organisations, NGOs, and Un agencies in ADF countries via its online portal.

“The CAW provides a veritable channel for countries to meet their global climate commitments,” remarked Kevin Kariuki, vice president of power, energy, and climate change at AfDB. “This facility will ensure that projects in Africa’s most climate-vulnerable regions are well positioned to attract significant funding, creating a win-win scenario where countries can achieve climate targets, while advancing sustainable development."

Enabling adaption projects in Africa

The launch was supported by a number of stakeholders from the countries that are set to benefit from the initiative who welcomed the new initiative.

“I would like to thank the African Development Bank and its partners, as these funds will finance the resilience of our people,” commented Côte d’Ivoire’s Minister of Environment and Sustainable Development, Assahoré Konan Jacques. “Specific activities have been identified and targeted, and I call on the African Development Bank to learn from the challenges other funds have faced, ensuring that CAW succeeds where others have struggled.”

Fatima Haram Acyl, the Chad Minister for Economy and Planning, added, “For countries like Chad, climate vulnerability is not just a term. Our people face floods, droughts, and immense losses, and we need real, fast-acting solutions. The CAW presents an opportunity to deliver transformative projects that strengthen our communities' resilience.”

Max Andonirina Fontaine, Madagascar’s Minister of Environment, surmised, “The CAW enables African nations to pilot initiatives that truly address our needs. With its flexible approach, we can, for example, fund ecotourism projects in Madagascar that both protect forests and create jobs – support that Africa urgently needs.”

Brian Civin, chief sales and marketing officer a AfriGIS, explains why geospatial data is the cornerstone of sustainable smart urban development

There is an increasing need for cities to become more efficient, sustainable, and liveable. Smart city initiatives explore how advanced technologies – such as data analytics, IoT, and artificial intelligence – can improve city operations and public services, reduce energy consumption, and enhance quality of life. They also support environmental sustainability, and create safer, more resilient communities in the face of challenges like climate

change and natural disasters.

With technology evolving rapidly, the idea of cities that can ‘think’ and ‘react’ to real-time data has become a feasible reality. However, there are numerous misconceptions and challenges that need addressing to move from theory to practice.

Urban planning

Geospatial data has long been essential in urban planning for optimising land use, infrastructure, and assessing risks like water flow. While traditional planning relies on this data, smart cities go further by integrating data-driven technologies into all aspects of urban life, though the concept of smart cities remains largely undefined and still evolving. Geospatial data is crucial in this context because it provides the foundational information needed to understand and manage the spatial dimensions of urban environments.

By integrating geospatial data, cities can optimise the placement and operation of resources like energy grids, water systems, and transport routes, leading to more efficient and sustainable urban planning. Plus, geospatial data enables real-time monitoring and management of services, supports emergency response and enhances decision-making processes by providing a detailed, location-based understanding of how different elements of a city interact.

Discover the full article in African Review November, available here

The investment underscores Ubiquity’s commitment to providing diverse offshore solutions for its clients. (Image source: Ubiquity)

Ubiquity, a leading global provider of customer experience, risk and compliance, and digital solutions, has opened a customer experience centre in Accra, Ghana

The facility is aimed at providing multilingual customer support solutions to global clients, primarily serving businesses in the financial services, healthcare, insurance and e-commerce sectors.

Located just minutes from Kotoka International Airport, it offers convenient access for international clients and is expected to unlock more than 500 professional employment opportunities for surrounding communities as per a company commitment.

“The decision to expand our global footprint into Africa comes with immense pride and excitement,” remarked Ubiquity co-founder & president, Sagar Rajgopal. “We are grateful to be a part of the thriving, cosmopolitan city of Accra which is virtually time zone neutral for the UK and EU. We are confident that its highly educated workforce, compassionate people, and favourable business environment can help us provide the best customer support and exceptional value for our partners and their customers.”

“Establishing a strong presence in Africa felt like a natural next step to support our clients with diverse offshore solutions, conducive time zone options and top talent access in a country like Ghana with such a booming economic climate,” Rajgopal added.

“This expansion allows us to enhance our service offerings and deliver even greater value to our clients while contributing to the local economy. We appreciate the warm welcome from the local community and look forward to welcoming many of its residents to our team as we continue to grow our presence here and across the region.”

-

-

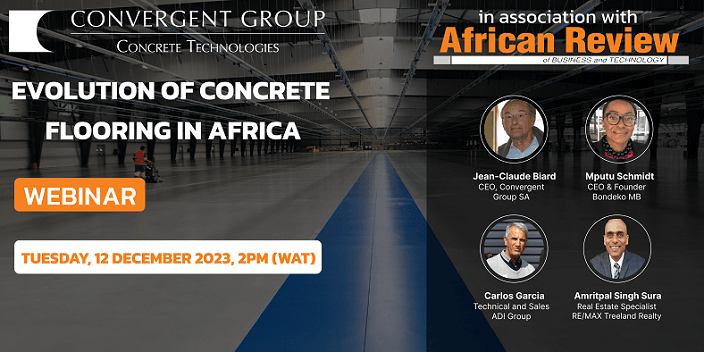

In the final webinar of its African Review-hosted 2023 campaign, Convergent Group explored its modern, eco-friendly concrete solutions for African projects

Such solutions – delivered to cut maintenance costs by eliminating hazardous silicate products – were showcased by company experts in the form of Jean-Claude Biard, SEO of Convergent Group SA; Mputu Schmidt, former CEO of Convergent Group SA and founder of Bondeko MB (exclusive distributor of Convergent Group in Africa); Carlos Garcia, technical and sales for ADI Group (Spanish distributor for Convergent Group); and Amritpal Singh Sura, external consultant for flooring treatments, former distributor of Convergent products in the Middle East.

“A number of projects we were doing in the Middle East required protection,” remarked Sura. “Longevity of protection requires a system which basically impregnates and becomes a densified surface as opposed to something which is topical and lifts off due to moisture migration. I found that being exposed to Convergent, it was important to stay focused on those systems in the Middle East. Jean-Claude, Mputu and I met several times in Dubai and there was emphasis on providing systems which were affordable and still ending up having a robust, lasting longevity of product. So you are not spending money all the time in order to maintain the finishes which you have already paid for.”

Over the course of the session, the participants guided the audience through the potential of cutting-edge lithium silicate technology for enhancing the protection of concrete surfaces, maximising cost-effectiveness and meeting sustainability targets.

-

In a comprehensive webinar hosted by African Review, a panel of professionals associated with Convergent Group explored new generation lithium silicate technology and why it is emerging as the optimum solution for concrete floor protection.

Robert Daniels, editor of African Review, was joined by Jean-Claude Biard, CEO of Convergent Group; Mputu Schmidt, former CEO of Convergent and founder of Bondeko MB, an exclusive distributor of Convergent; Hicham Sofyani, president of Texol; Carlos Garcia, technical and sales for ADI Group; and Marc Puig, commercial manager of Comace Import.

Each providing a unique angle, the panellists combined to provide a masterclass around concrete treatments and the increasing challenges around them, explaining to attendees how to choose the right formula for their requirements and touching on issues such as why lithium densifiers are better than sodium and potassium densifiers.

Throughout the session, those watching were treated to informative case studies showcasing how Convergent eco-friendly products are increasing abrasion resistance, raising ease of maintenance, and ensuring the highest quality gloss retention.

By the end of the webinar, a majority of attendees (many of which had not had much experience with Convergent) expressed their interest in using the company’s new generation lithium silicate technology with the rest indicating their desire to learn more about Convergent and its products. Watch the webinar, in full, to discover why viewers were convinced and learn more about advanced floor care solutions for your operations.

-

Presenting on an African Review-hosted webinar, Martin Provencher, global industry principal for mining, metals and materials at AVEVA, explored the digital transformation of mining operations and its impact on sustainability.

“Sustainability is becoming a key aspect for mining operations,” remarked Provencher. “If we look at the latest EY research on the top ten business risks and opportunities for mining and metals globally in 2023, ESG remains at the top. Of course, most companies have environmental goals or are expected to reach a net zero emission by 2050, which is a pretty aggressive target. Many of them are targeting 30% reduction by 2030; seven years from now. So there is a lot of action that needs to take place quickly to get there. It is possible to get there, but we need to make sure we are doing this correctly.”

Fast becoming a huge part of ESG initiatives is fleet electrification where particular progress is being made in underground mines. While some countries are certainly more advanced than others here, Provencher noted that 40% of total emissions from the mining industry come from diesel trucks, making EVs a very attractive low-hanging fruit for companies to pursue.

There are, however, a number of challenges associated with bringing in electric vehicles which remains a barrier for introduction. One of the predominant reasons, is the limited range of EVs against diesel counterparts. To mitigate this, Provencher continued, data management is key and ensuring a strong grasp of real-time information coming in will show operators when machinery needs to be charged, allowing them to plan effectively for maximum efficiency on site.

Indeed, this is but a small advantage that digitalisation can bring to the mining industry as it grapples to meet ESG goals while achieving production targets. By getting a better grip of their data and using it to empower tools such as artificial intelligence, advanced analytics and machine learning, companies can achieve tangible benefits such as reduce downtime, enhance worker safety, cut operating costs and, of course, ensure compliance with environmental regulations and targets.

Through the course of the webinar, Provencher outlined this in more detail and explored AVEVA’s suite of cutting-edge software solutions, specifically designed to help mining companies make progress on their digitalisation journey and empower their operations.

Watch the full webinar, completed with detailed case studies and an insightful Q&A session.

-

-

-

Convergent, in association with African Review, has held a detailed webinar exploring the usage and effectiveness of lithium silicates and densifiers over traditional methods of concrete surface management which often struggle to meet the increasing challenges posed by concrete surface management.

Convergent experts including Mputu Schmidt, CEO of Convergent; Carlos Garcia, product manager end-user solutions, construction chemicals, Spain and Portugal for the RD Group; Matteo Mozzarelli, CEO of concrete Solutions Italia; and Jean-Claude Biard, global senior executive for the Convergent Group, presented across the session.

Together, they delved into the latest cost-effective application methods for long lasting finishing of concrete that can help reduce maintenance costs and avoid unexpected repair action. In addition, they examined the advancements in technologies that can sustain increased abrasion resistant stains and ensure gloss retention to the highest quality.

As part of the webinar, the representatives explored case studies including a case in DRC where a medical centre had been constructed with a low-quality concrete floor. The customer was considering completely replacing the floor but instead, Convergent put forward a special treatment with its 244+ Pentra-Sil lithium hardener, densifier and sealer. With this solution, Convergent can increase the hardness of a surface by up to 40% and therefore saved the customer significant recuperation costs over a complete replacement. Convergent were happy to report that the solution was perfect for the facility and the customer was pleased to avoid the extra construction work that would have been required for a complete replacement.

Watch the full webinar, including more information about Convergent’s innovative solutions.

Launch of the facility will enable the African Development Bank to increase the reach of the CAW's efforts. (Image source: AfDB)

African Development Bank (AfDB) has unveiled its new Climate Action Window (CAW) Technical Assistance Facility at COP29

Before the conference, which is running in Baku from 11-22 November, the organisation stated its intention to mobilise additional resources for climate action in Africa and to launch a new approach to assess African economies. Following this, it has taken a ‘major step’ to address the continent’s climate finance gap by launching a new funding call with an initial allocation of US$56mn.

The CAW Technical Assistance Facility will support the preparation, financing and implementation of adaption and mitigation projects aligned with the Paris Agreement, Nationally Determined Contributions (NDCs), and National Adaption Plans (NAPs). It will aim to transform the development of climate projects across 37 low-income countries in the continent and is backed by funding commitments from partners such as the United Kingdom, Netherlands, Germany, and Switzerland. It will be accepting proposals from governments, regional organisations, NGOs, and Un agencies in ADF countries via its online portal.

“The CAW provides a veritable channel for countries to meet their global climate commitments,” remarked Kevin Kariuki, vice president of power, energy, and climate change at AfDB. “This facility will ensure that projects in Africa’s most climate-vulnerable regions are well positioned to attract significant funding, creating a win-win scenario where countries can achieve climate targets, while advancing sustainable development."

Enabling adaption projects in Africa

The launch was supported by a number of stakeholders from the countries that are set to benefit from the initiative who welcomed the new initiative.

“I would like to thank the African Development Bank and its partners, as these funds will finance the resilience of our people,” commented Côte d’Ivoire’s Minister of Environment and Sustainable Development, Assahoré Konan Jacques. “Specific activities have been identified and targeted, and I call on the African Development Bank to learn from the challenges other funds have faced, ensuring that CAW succeeds where others have struggled.”

Fatima Haram Acyl, the Chad Minister for Economy and Planning, added, “For countries like Chad, climate vulnerability is not just a term. Our people face floods, droughts, and immense losses, and we need real, fast-acting solutions. The CAW presents an opportunity to deliver transformative projects that strengthen our communities' resilience.”

Max Andonirina Fontaine, Madagascar’s Minister of Environment, surmised, “The CAW enables African nations to pilot initiatives that truly address our needs. With its flexible approach, we can, for example, fund ecotourism projects in Madagascar that both protect forests and create jobs – support that Africa urgently needs.”

The Lintec CSD2500B ensures uninterrupted operations, and its modular construction delivers cost efficiencies and easy installation. (Image source: Lintec & Linnhoff)

A Lintec CSD2500B Containerised Asphalt Mixing Plant has been supporting Power Construction Corporation of China (POWERCHINA) in its work on the New Dodoma Msalato International Airport in Tanzania

The project is aimed at enhancing the infrastructure and connectivity of Tanzania’s political capital and the wider East African region. Once fully operational, it is expected to accommodate 1.5 million passengers annually. With investment from the Tanzanian Government and a loan from the African Development Bank, construction is taking place in two phases. The first is focused on the runway and terminal, while the second will be implemented based on demand.

For its work on the project, POWERCHINA purchased the mixing plant from Lintec & Linnhoff which began production in September 2023. The plant has been helping to build key facilities since this time, including a new apron, taxiway, runway, and auxiliary roads.

Construction has also been underway on new hangars, terminals, firefighting units, electromechanical installations, and a new airfield tower. As a result of these efforts, the project has reportedly reached the halfway point and is expected to be completed by April 2025.

Excelling in Tanzania

The Lintec Containerised Asphalt Mixing Plants feature a modular construction that allows for easy transportation and convenient installation. The Lintec CSD2500B model has a capacity of 160 tph and a batch size of 1650/1600 kg.

Prioritising sustainability with pollution control units and optional recycling units, the design also ensures security with a central lockable access point and features convenient walkways along with staircases for easy maintenance. These are but some of the features that led to POWERCHINA purchasing the plant for the project – a decision that continued the company’s long-standing relationship with Lintec & Linnhoff having used it for a number of projects dating back to 2010.

“Several factors drove our decision to invest in the Lintec CSD2500B Containerised Asphalt Mixing Plant,” said a spokesperson from POWERCHINA. “Firstly, we prioritise safety and reliability in all our operations, and with Lintec & Linnhoff’s German-engineered equipment, we are confident in the highest standards of performance and quality. In addition, the Lintec CSD2500B’s containerised design ensures uninterrupted operations despite Tanzania’s challenging rainy seasons, while its modular construction delivers cost efficiency through low transport expenses and easy installation.”

In Kenya, a Linnhoff TSD1500 Asphalt Mixing Plant has been proving its worth on rural road projects in Kenya. Click here to learn more

Providing fresh air to underground workers, removing dust and noxious gases, regulating temperature, there are few aspects more critical to a modern mine than an effective ventilation system

With worker safety now one of the most paramount concerns of mining companies, it has never been more important for them to ensure an effective, well-planned underground mining ventilation system is in place.

Fortunately, there are a range of innovative equipment and service providers who are able to support mines as they seek to provide air flows in sufficient quantity and quality to ensure their workforce is safe. Take the likes of Unique Ventilation and Support Systems (UVSS), one of the largest ventilation manufacturing companies in Africa. With a client based across the continent – working with household names such as Anglo American, Goldfields, Sibanye, Impala, and more – UVSS boasts more than 85 years of experience in the sector, and is utilising this in its mission to become the market leader in Africa for the design, development, fabrication and supply of total integrated mining and industrial related ventilation systems, underground support and ancillary equipment.

African Review held a short Q&A with Jeremy Pettitt (JP), group - sales & business development manager at UVSS, to understand more about this vital service the company provides to the sector. Discover the full article in the November issue of African Review here

Genie, a leader in the aerials industry, has launched a new, future-focused design for its core slab scissor lift product line

The company has further improved the performance and lowered the total cost of ownership for Next-Generation Genie GST-1932, GS-2632, GS-3232, GS-2646, GS-3246, and GS-4046 scissor lifts. A noticeable change in the form of a curved linkage design results in reduced machine weight, allowing Genie to use right-sized components for lower replacement part cost.

“Genie’s Next-Generation Scissor Lifts are redefining the standard for slab scissor lifts and moving this classic MEWP category into the future,” remarked Christian Dube, senior global product manager. “Our priority when redesigning these lifts was to drive lower cost of ownership, improve serviceability, and enhance the user experience – all while delivering the quality that our customers and the industry expect from Genie.”

The company has also sought to eliminate rust and limit opportunity to damage through a number of design changes including a new chassis to mitigate stagnant water and reinforced steel in targeted locations to reduce damage.

“On their own, each individual update is an incremental improvement. But, when considered together as a system, and across the product line, the result is a family of machines that add value by reducing costs while improving performance and serviceability,” Dube added.

Overall, there are fewer serviceable components than with previous generations; of the components that remain, at least 70% have commonality across the product line. This simplifies machine fleet management and should increase uptime. According to Genie, fleet management is further improved by incorporating a consistent parts layout in easy-to-access locations; a win for service technicians who work on multiple models.

Operators are also set to benefit from a re-designed platform to improve productivity when working at height. On the popular GS-1932, standard fixed guard rails allow users to drive through most common doors without the need to pause and fold guardrails down. The platform is 20% larger, offering more room for two people to work comfortably indoors. Across the range, operators will notice other subtle details that enhance comfort at height.

Genie has also highlighted that the new Smart Link platform controller is completely redesigned to be 30% lighter than the previous version, complete with a more ergonomic design. Because it is modular, parts of the controller can be replaced without requiring replacement of the whole – another example of reducing parts replacement cost.

Geraldine Sande, channel sales leader for Schneider Electric East Africa. (Image source: Schneider Electric East Africa)

Schneider Electric East Africa, a specialist in energy management and automation, has launched an eCommerce platform

Designed to cater to a diverse market, it includes tier 2 channels and represents a step towards modernising its procurement process and reinforces the company’s market presence. This is the assessment of Geraldine Sande, channel sales leader for Schneider Electric East Africa, who commented, “With the eCommerce platform, customers can access the required products locally, conveniently, faster and at their desired location without intermediary intervention.”

The portal lists a range of products and primarily targets end users in the residential space who would often have to travel far to a distributor, and commercial customers.

Sande explained that the platform also targets ‘specifiers’ – the individuals involved in projects and those who create bills of quantities (BOQs) or requests for quotations (RFQs) and need to know the available product options, as well as companies that require reliable supply chains for maintenance and operations.

“We noticed a gap in the market in terms of brand visibility in Kenya,” Sande continued. “Many people would ask if Schneider Electric was present in Kenya because we did not have a website (the website will go live in 2025) or any formal digital footprint. Instead, customers would find our partners on other Schneider Electric subsidiary platforms. The customer would also need to have a list of partners online and thus have insight about which solution is found from which channel partner.

“Given this, we felt there was a need to utilise another vehicle to be in front of the customer whenever someone is searching for a product and ensure the product is easily accessible, aside from going through our existing distribution channels.”

Sande stressed that the new platform is not designed to erode the market share of resellers and distributors but can instead bring potential benefits to their businesses.

“From the distributor's perspective, the platform will benefit them by increasing their sell-out. Distributors often hold a lot of stock, and the e-commerce platform provides them with another avenue to reach customers they were not previously tapping into. This represents an incremental business opportunity for our distributors,” concludes Sande.

The flexibility of the solution enables it to accommodate various courses in the hydraulic and pneumatic training environment. (Image source: Bosch Rexroth)

Bosch Rexroth Africa’s Training Department has launched a modular training workstation in order to enhance its training services and address the shortage of hydraulic and pneumatic skills in Africa

Available to customers, training, providers and Technical and Vocational Education and Training (TVET) colleges as well as universities, the workstation is designed to be customisable and adaptable – enabling it to meet unique training needs of users.

The workstation aims to provide participants with practical experience with real-world equipment and machinery for industries such as fitting, millwright, diesel, mechanics, earth-moving and mechatronics and can accommodate various courses.

Building a skilled workforce

Bosch Rexroth Africa Training Department is a registered and accredited training provider and this new initiative is aimed at supporting continuous learning and upskilling of crucial skills to be build a more competent workforce.

“By demonstrating the practical benefits and real-world applications of these training workstations, we hope to inspire current and future professionals to embrace continuous learning and development,” remarked Allen van Gert, group training manager.